KLEAN WELDING SOLUTIONS

LLC

Your Trusted Partner for Quality Welding and Fabrication Services

A welding business repairs, restores, and assists in building metal-based items. Our comprehensive services include flux core welding, aluminum welding, plasma cutting, metal fabrication, dump truck box repair, and more. With a commitment to excellence, we cater to various projects throughout the year.

Expert Welding Solutions for Your Metal Projects

Professional Welding, and Steel Fabrication Services which Services all 3 Major Forms of Welding SMAW

Three Prevalent types of Welding Techniques include:

- 1. Arc Welding (SMAW): This method involves using a consumable electrode to generate an electric arc between the electrode and the base material.

- 2. MIG Welding (GMAW): In this technique, a wire electrode and a shielding gas are utilized to create a weld.

- 3. TIG Welding (GTAW): TIG welding utilizes a non-consumable tungsten electrode along with a shielding gas to produce a precise and clean weld.

video coming soon on youtube

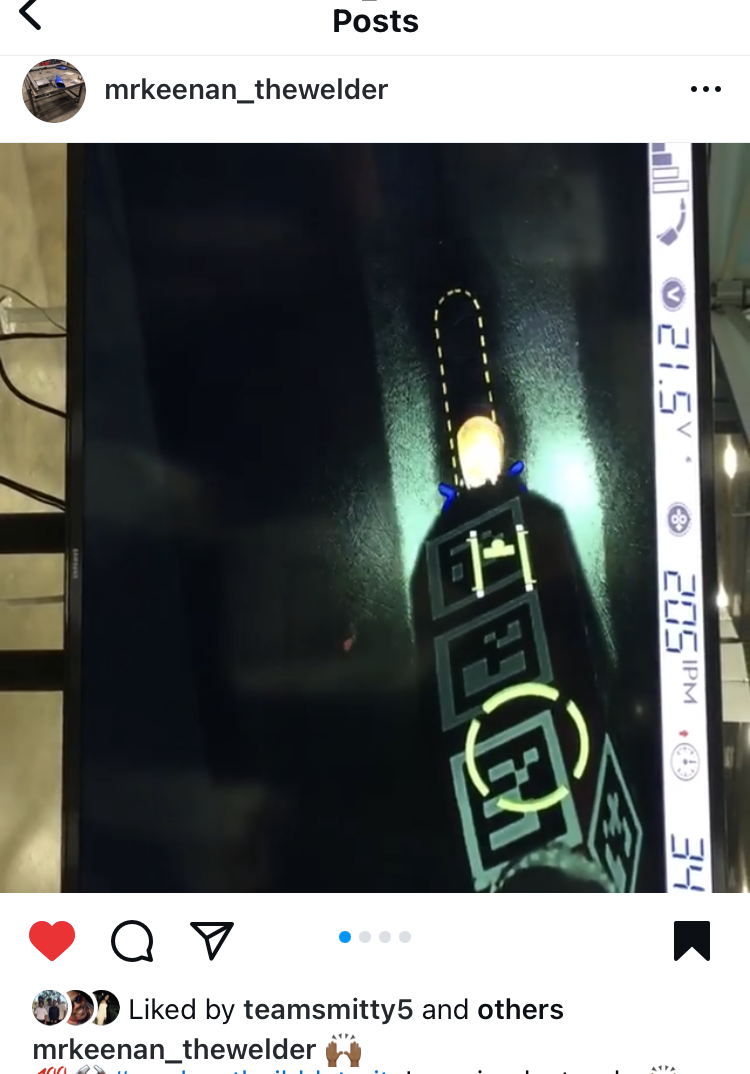

VIRTUAL REALITY (VR) MIG WELDING SIMULATOR CHALLENGE!

at the "READY SET BUILD DETROIT" 2018 CONVENTION!

"This was my first big Convention as a stdent welder. I seen a VR Stimulator, with a Mig Gun .... the rest was histroy!

What you think I Scored ??

It was a blast trying for the first time with a little friendly words exchanged, check out the full video and remember Being humble is a force... to be mastered!

LEARN 2 BURN

Our team consists of highly qualified and motivated professionals, who are all experts in their field. With many years of experience in the industry, they have the expertise to provide comprehensive, first-rate services to our clients.

STICK

S.M.A.W

- Arc Formation: An electrical arc is produced when the electrode contacts a metal surface.

- Flux Coating: The electrode has a special coating called flux.

- Filler Material: The electrode is also a source of filler material.

- Slag Formation: The flux coating causes a layer of slag to form on top of the weld.

- Slag Removal: After welding, the slag needs to be removed.

MIG

G.M.A.W

MIG welding (Metal Inert Gas welding) is an arc welding process that involves the following steps:

- A continuous solid wire electrode is fed through a Welding gun.

- The Wire melts and creates a permanent joint by joining two base materials together.

- A Shielding Gas is sent through the welding gun to protect the weld pool from contamination.

- The process is achieved under the protection of an inert gas, preventing oxygen and other contaminants from reacting with the molten meta

TIG

G..T.A.W

- TIG welding joins metal parts using a tungsten electrode.

- An Inert gas (usually argon) shields the electrode and the workpiece to prevent oxidation.

- The Electrode and Workpiece produce a high-temperature arc that melts the metal, forming a weld pool.

Key Highlights of Our Welding Business

At KLEAN WELDING SOLUTIONS LLC, we take pride in providing exceptional welding and fabrication services. Explore some of our key features below:

Aluminum Welding Specialists

Our team excels in precision aluminum welding, ensuring durable and precise results for your projects.

Expert Metal Fabrication

Experience superior metal fabrication services tailored to meet the unique requirements of each project.

Flux Core Welding Excellence

Benefit from our expertise in flux core welding, delivering strong and reliable welds for structural integrity.

Steel Construction Solutions

Specializing in steel construction, we provide comprehensive solutions for a wide range of industrial and commercial projects.

5jobs

1000+

Happy Clients

10+

Years of Experience

©Copyright. All rights reserved.

We need your consent to load the translations

We use a third-party service to translate the website content that may collect data about your activity. Please review the details in the privacy policy and accept the service to view the translations.